The Difference Between Color Hardener, Integral Color, & Antique Release

Contractors often have strong feelings when it comes to color hardener, integral color, and antique release. While the project may dictate the product to a certain degree, often it’s our own preference that drives the decision. But are you really using the best product for the job? And how can you best explain the use of these items to homeowners? Let’s take a deep dive into the differences and pros / cons of each!

-

Color Hardener 60 LB Pail

$47.00 Select options This product has multiple variants. The options may be chosen on the product page

All about color hardener

Color hardener, strengthens the slab surface by making it denser, is broadcast on top of wet concrete and then troweled in is broadcast on top of wet concrete and then troweled in. Affecting only the top surface layer, it provides the first coat of color. This popular coloring technique provides an intense color.

Pros:

- Since color hardeners increase concrete’s strength, they’re great for use in climates subject to freeze-thaw cycles or for floors with high foot traffic.

- Use when you want vivid color.

Cons:

- This product is manually applied so it’s more labor intensive to use.

- Since the color is only incorporated into the top layer, if the concrete gets chipped, it’ll be a process to color match.

- Care should be taken to protect the areas around where the product is applied to avoid stains.

-

Proline Color Packs

$43.00 Select options This product has multiple variants. The options may be chosen on the product page

All about integral color

Integral color is directly mixed into wet concrete so the color is already incorporated when it’s poured out of the truck. Our Proline Powdered Integral Colors can be used in ready mix, cast-in-place, architectural pre-cast, and much more. Make sure the product, which is packaged in 25-pound bags, isn’t sprinkled onto the surface since it’s designed for mix-in only. We also offer color packs. 1 bag of the color pack can be added to 1 bag of concrete for smaller projects.

Pros:

- If the concrete is chipped, you don’t need to try to color match since the concrete is colored throughout.

- Mixed into wet concrete so easy to use.

- Good option for difficult projects, like when there are vertical surfaces.

Cons:

- The product is usually done at a plant so contractors don’t have as much control.

- The resulting color may not be as consistent due to the makeup of the concrete.

-

Antique Release – Concrete Colors 30 LB Pail

$83.75 Select options This product has multiple variants. The options may be chosen on the product page

All about antique release

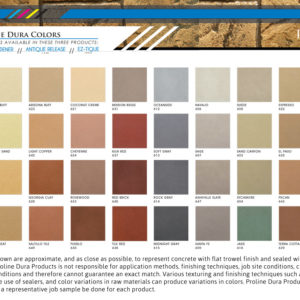

This powdered color (available in over 40 colors) is broadcast over the concrete and then stamped. It adds depth to a concrete pattern as it’s generally a darker color than the base color. After the concrete has cured, the antique release is removed by brushing and rinsing. Remove more or less of the product to achieve the desired effect.

Pros:

- One product adds color while serving as a release agent.

Cons:

- Applied by hand or brush so more labor intensive.

- The timing is tricky – start stamping as soon as the product is applied but don’t get too far ahead of the stamping.

Contact the pros at Calico Construction Products

All three products can be used as color for any stamp products. It all depends on what the contractor prefers and the preferred outcome of the concrete project. Need some help weighing the pros and cons? Contact us today at 800-221-9469 and we’ll help you figure it out! Don’t forget to check out our FAQs and blog posts for more information.

Categories: Color & Stain